The Need

Coal is BC’s largest export commodity. It is valued at over $3 billion dollars annually (view report) and supports more than 26,000 jobs.

Core samples of metallurgical coal – used to make coke, an essential ingredient in steel production — are ‘washed’ before quality testing in the laboratory. Coal from southeast BC’s coal mines contains ash which must be washed off to produce a clean sample for accurate coal and coke quality characterization. This analysis is a vital step in assessing the economic value of a project, and must be reliable. Currently, coal samples are analysed using the float/sink method which uses organic chemicals such as white spirit, perchloroethylene (PCE) and methylene bromide. This can have a negative effect on coking coal and potentially exposes laboratory technicians to carcinogenic materials. An alternative and effective waster-based washing method that can be used at a commercial scale would remove the need to use organic chemicals in the process, along with associated health and environmental risks.

Project Goals

To determine if the water-based ‘Roben Jig’ (also known as ‘Boner Jig’) process can be commercially used to wash a broad range of coal types found in British Columbia coking coal basins to an equivalent or superior standard to traditional methods.

Project Benefits

The main benefit of washing coal samples using the water-based Roben Jig is to decrease the safety risk associated with the handling and use of organic liquids such as PCE. PCE is a known carcinogen and poses a safety hazard for laboratory operators who must handle the chemicals carefully to avoid exposure.

Investigations have also found that PCE can influence the properties of the coal to be tested, reducing the reliability of the test, and perhaps leading to over- or under-valuing of a potential coal mine project.

Survey Area

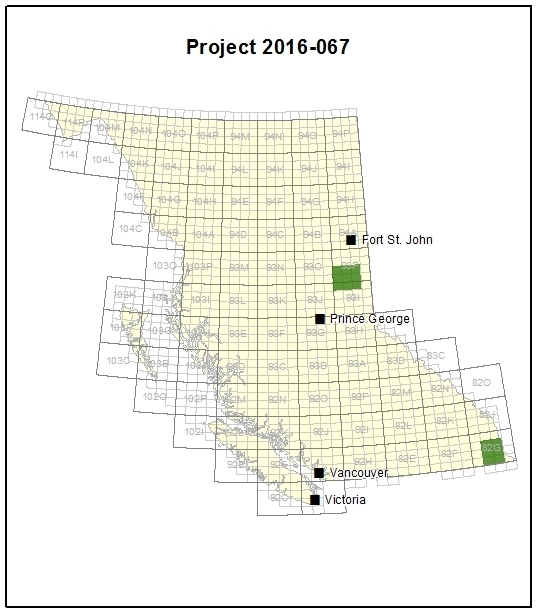

The four raw coal samples tested in this project were collected from coalfields in northeast BC, between Prince George and Fort St John, and in southeast BC, east of Cranbrook. The coal samples were shipped to an accredited coal testing laboratory in Calgary.

How was the data collected?

This project evaluated clean coal products resulting from two methods of washing coal: traditional organic liquids float/sink and Roben Jig separation. The traditional float/sink method uses chemicals of different densities to separate the particles of the coal sample, whereas the Roben Jig is a device that allows the sorting of coal particles based on density to occur as the coal is jigged up and down in a column of water. Each coal sample was washed using both the jig method and the organic liquids method yielding two clean coal composites per coal type, and the basic coal quality parameters were assessed and compared.

What was found?

For each of the samples tested during the first phase of the project, the Roben Jig was able to clean the coal to create a sample that offered the same or more realistic measures of the coal quality characteristics when compared to the float/sink-based sample, without exposing laboratory workers to harmful chemicals.

It was found that higher ash particles did contaminate lower density slices in the jig, but it is unknown if this misplaced material impacted coke quality.